The aerospace world is buzzing with news of Dr. Tang’s electric thrust engine. Revealed on May 6, 2025, this device turns air into plasma to create lift without jet fuel. It’s already shown it can match traditional engines in power. Airlines are taking notice as the technology promises massive cuts in both fuel costs and carbon emissions. The question now isn’t if this will change aviation, but how quickly the industry will adapt to this game-changing innovation.

While engineers have spent decades working to develop cleaner aircraft propulsion, a major breakthrough in electric thrust engine technology was announced on May 6, 2025. Dr. Tang‘s groundbreaking system uses only electricity to generate thrust without traditional jet fuel. The technology transforms ordinary air into thrust-producing plasma with enough power to lift a 2.2-pound steel ball during demonstrations. The system could significantly reduce the aviation industry’s carbon footprint.

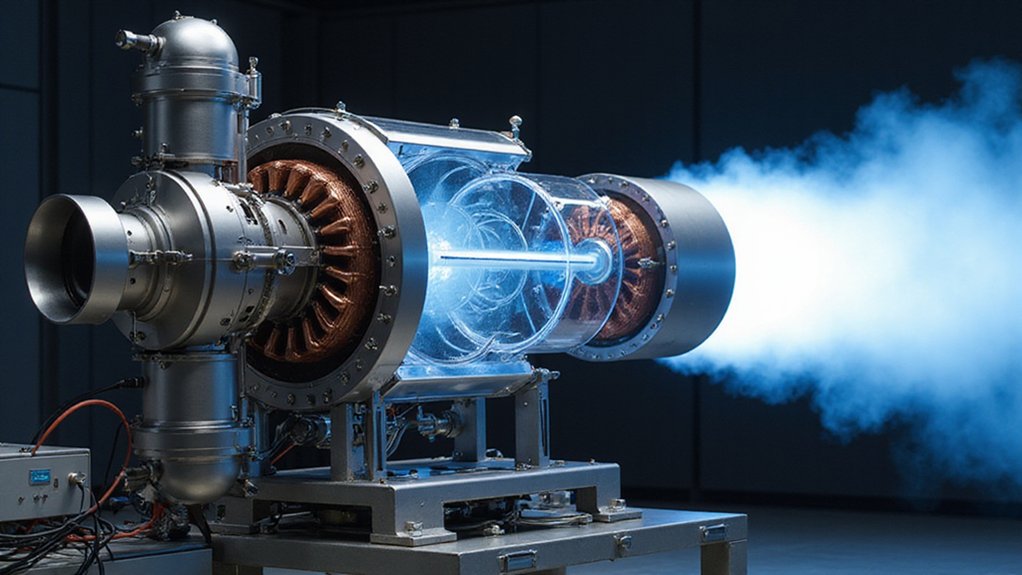

The system works by compressing air through a turbine compressor to create a high-pressure environment. A microwave ionization chamber operating at 2.45 GHz then excites air molecules, stripping electrons from atoms. This creates plasma at thousands of degrees Celsius that rapidly expands upon exit, generating jet thrust comparable to conventional engines.

Unlike NASA’s existing plasma thrusters that require xenon gas, Tang’s innovation uses atmospheric air, making it more practical for commercial aviation. This advancement arrives as several companies accelerate their electric propulsion development efforts.

Tang’s breakthrough plasma engine harnesses regular air instead of exotic gases, revolutionizing the commercial aviation landscape.

Wright Electric is preparing to test its 2-megawatt WM2500 electric propulsion system after completing simulated high-altitude testing at a NASA facility. They’ve built a dedicated thrust test stand that will initially use 500 kW power with their first-generation electric motor. The company has established a new test infrastructure using a converted Lycoming LF507-1F turbofan engine for comparative analysis.

Meanwhile, GE Aerospace showcased hybrid-electric propulsion technologies at Verticon 2025 this March. Their systems aim to optimize performance throughout flight profiles while reducing environmental impact. This innovation aligns with the global push for green revolution in transportation, similar to the advancements seen in electric vehicles.

The efficiency benefits are substantial. These electric and hybrid systems target up to 25% improvement in fuel efficiency and greatly reduce CO2 emissions. Some technologies even recover water vapor from engine exhaust, reducing NOx emissions and contrail formation.

Industry collaboration has been vital to these developments. Wright Electric received funding from the US Department of Energy and partnered with multiple aerospace organizations. Several companies are pursuing parallel paths toward electric aircraft propulsion.

The first test stand usage is planned for summer 2025, with next-generation aircraft development expected to begin shortly after. Aircraft developed during this period could remain in service into the 2060s, potentially marking the beginning of the end for conventional jet fuel.

References

- https://www.sustainability-times.com/research/the-end-of-jet-fuel-next-generation-engine-uses-electricity-alone-to-generate-thrust-in-historic-aerospace-breakthrough/

- https://www.ainonline.com/aviation-news/futureflight/2025-05-07/wright-prepares-expand-electric-propulsion-system-tests

- https://www.geaerospace.com/news/press-releases/ge-aerospace-showcases-advances-hybrid-electric-propulsion-verticon-2025

- https://www.flightglobal.com/engines/wright-electric-poised-for-electric-engine-ground-tests/162869.article

- https://www.laranews.net/next-gen-aircraft-propulsion-systems-hybrid-electric-hydrogen-and-saf/