MIT engineers just cracked a code that sounds too good to be true. They figured out how to turn aluminum trash and seawater into hydrogen fuel. Not regular hydrogen production that spews out 11 kilograms of CO₂ per kilogram of hydrogen. This process releases just 1.45 kg. That’s an 87% drop in emissions.

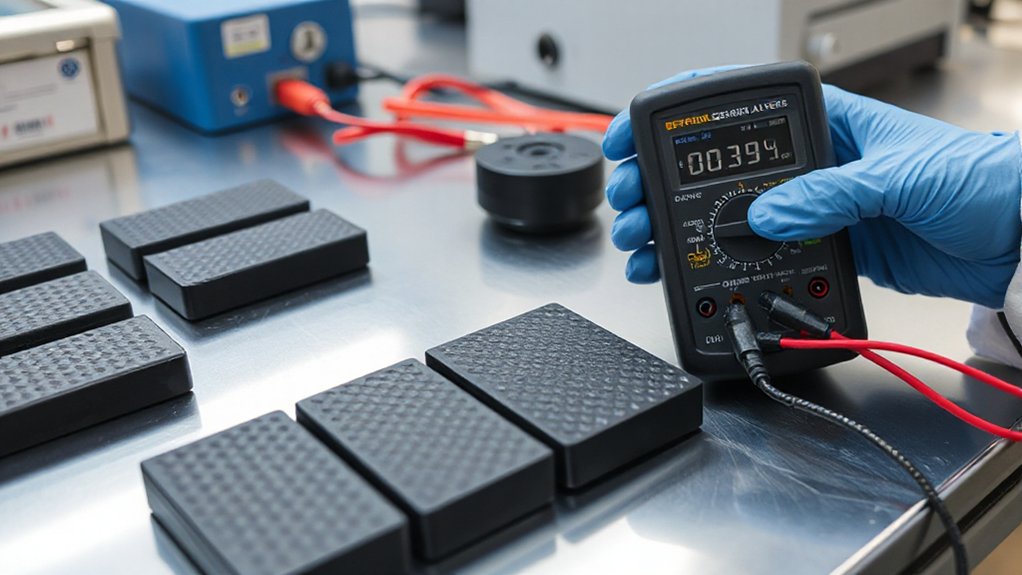

The science isn’t complicated. Mix aluminum with water, get aluminum hydroxide and hydrogen gas. Room temperature reaction, no fancy equipment needed. The catch? Aluminum oxidizes fast, forming a barrier that kills the reaction. MIT’s team solved this with pretreatment methods that keep the aluminum reactive. The breakthrough involves painting a gallium-indium eutectic mixture on aluminum surfaces, which penetrates internal grain boundaries and maintains reactivity.

Room temperature aluminum-water reaction produces hydrogen gas—if you can stop oxidation from killing the process first.

Here’s where it gets interesting. They’re using aluminum scrap, old soda cans, whatever metallic junk is lying around. Combine that with seawater, which covers 71% of Earth’s surface, and suddenly hydrogen production isn’t limited to specialized facilities anymore. Remote locations, coastal areas, anywhere with access to aluminum waste and water becomes a potential hydrogen source.

Hydro, the aluminum company, already produced the world’s first batch of recycled aluminum using hydrogen power in 2023. They switched from natural gas with minimal infrastructure changes. Other aluminum companies are watching closely. Transportation companies too, since this hydrogen works in engines and fuel cells.

The traditional hydrogen industry must be sweating. Their methods require massive infrastructure, complex storage systems, and transportation nightmares. This process happens wherever you have aluminum waste and water. No pipelines, no specialized tankers, no billion-dollar facilities. This approach could address the energy reliability issues that often plague renewable sources during extreme weather events. The U.S. Department of Energy’s $750 million allocation for clean hydrogen projects signals major shifts in how governments view decentralized hydrogen production.

The implications stretch beyond clean energy buzzwords. Waste aluminum becomes valuable. Seawater transforms from salt-laden nuisance to fuel source. Remote communities gain energy independence. Transportation sectors get cleaner fuel options without rebuilding entire fleets.

MIT’s research demonstrates that sometimes the best solutions hide in plain sight. Aluminum and water, two of Earth’s most common substances, combining to produce ultra-clean fuel. The chemical bonds break, reform, create something new. Simple chemistry solving complex problems.

The process works. The emissions numbers don’t lie. Now it’s about scaling up, moving from successful tests to widespread adoption. Given the materials involved and emission reductions, that shift might happen faster than anyone expects.

References

- https://news.mit.edu/2021/using-aluminum-and-water-to-make-clean-hydrogen-fuel-0812

- https://www.lightmetalage.com/news/industry-news/recycling-remelt/aluminum-companies-look-to-hydrogen-as-a-sustainable-fuel-for-remelt-operations/

- https://www.hydro.com/en/global/media/news/2023/worlds-first-batch-of-recycled-aluminium-using-hydrogen-fueled-production/

- https://www.fastechus.com/blog/generating-hydrogen-water-aluminum-reaction/

- https://www.techexplorist.com/hydrogen-scrap-turning-soda-cans-seawater-clean-energy/99675/