LEGO’s new $1 billion factory in Vietnam aims to transform sustainable toy manufacturing. Located in Binh Duong Province, the facility will be completely carbon-neutral, powered by renewable energy including on-site solar panels. Set to begin production in 2025, it’ll create up to 4,000 jobs while maintaining LEGO’s strict quality standards. This project represents LEGO’s commitment to environmentally responsible manufacturing without compromising the creative play experiences children love worldwide.

While global manufacturing faces increasing pressure to reduce environmental impact, LEGO Group has made a groundbreaking move with its new $1 billion factory in Vietnam’s Binh Duong Province. Located just 50km from Ho Chi Minh City, this 44-hectare facility represents the company’s sixth global manufacturing site and its second in Asia.

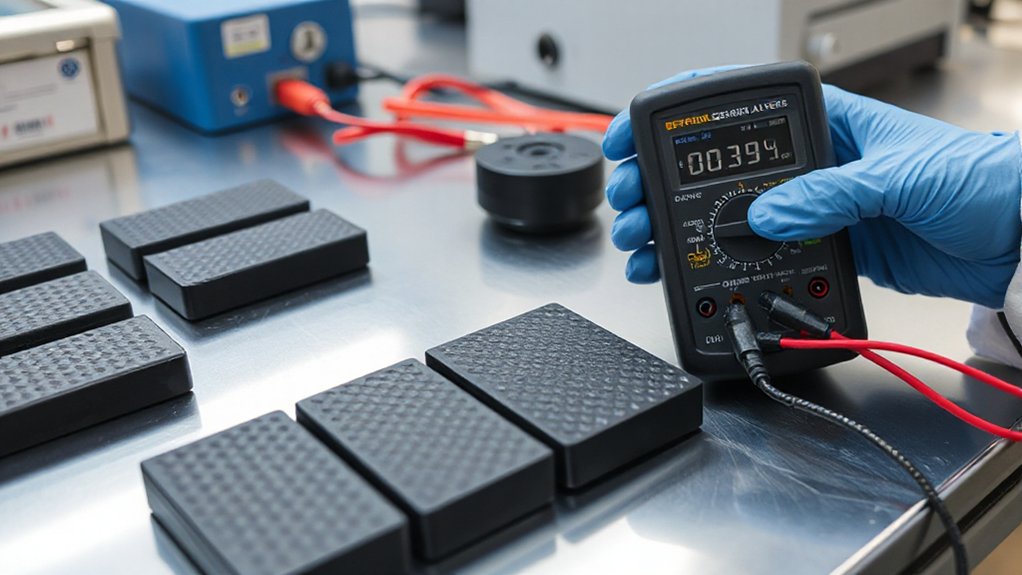

The Vietnam factory stands out as LEGO’s first carbon-neutral production facility. It’s powered primarily by renewable energy sources, including on-site solar generation. The factory will operate on 100% renewable energy by early 2026, marking a significant milestone in sustainable manufacturing. This approach aligns with the company’s ambitious sustainability goals for 2030. The factory also uses sustainable packaging materials and implements energy-efficient processes throughout its operations.

LEGO’s Vietnam facility sets new standards with carbon-neutral production powered by renewable energy and sustainable operations.

Construction of the facility began in late 2022, with production starting in early 2025. The factory features state-of-the-art technology for molding, manufacturing, and packaging LEGO products. Its high-bay warehouse optimizes material storage and improves supply chain efficiency. This innovation reflects the broader trend where technological improvements are driving the shift toward clean energy across manufacturing sectors.

The economic impact of this investment is significant for Vietnam. The factory is expected to create up to 4,000 jobs over the next 15 years. These positions span production, engineering, quality assurance, and logistics. LEGO is also offering training programs to develop advanced manufacturing skills in the local workforce.

This expansion strengthens LEGO’s presence in the Asia-Pacific region, where the company has seen double-digit growth since 2019. The increased production capacity will make LEGO products more accessible to children and families throughout Asia.

Beyond manufacturing, LEGO has committed to promoting learning-through-play initiatives for Vietnamese children. The company is engaging with local communities through outreach programs and supporting educational development aligned with STEM principles. Every element produced undergoes rigorous validation to ensure the highest quality standards are maintained for all LEGO products.

Looking ahead, LEGO plans to further reduce carbon emissions across its supply chains and expand solar infrastructure at the site. The Vietnam factory isn’t just producing colorful building blocks – it’s constructing a model for how global manufacturing can balance production needs with environmental responsibility.