The electric vehicle industry faces a significant slowdown as major automakers cancel planned battery factories. Companies are backing away from earlier green commitments due to high production costs and uncertain demand. Ford, GM, and others have delayed or scaled back billion-dollar projects. Meanwhile, consumers remain hesitant about EVs, citing concerns over charging infrastructure and vehicle prices. This industry pullback raises questions about the future pace of transportation’s green shift.

Why are electric vehicle manufacturers suddenly hitting the brakes? The once-booming electric vehicle industry is facing serious challenges as automakers cancel plans for battery factories and scale back production targets. Global vehicle sales growth is expected to reach only 2.7% in 2025, putting pressure on the entire automotive sector.

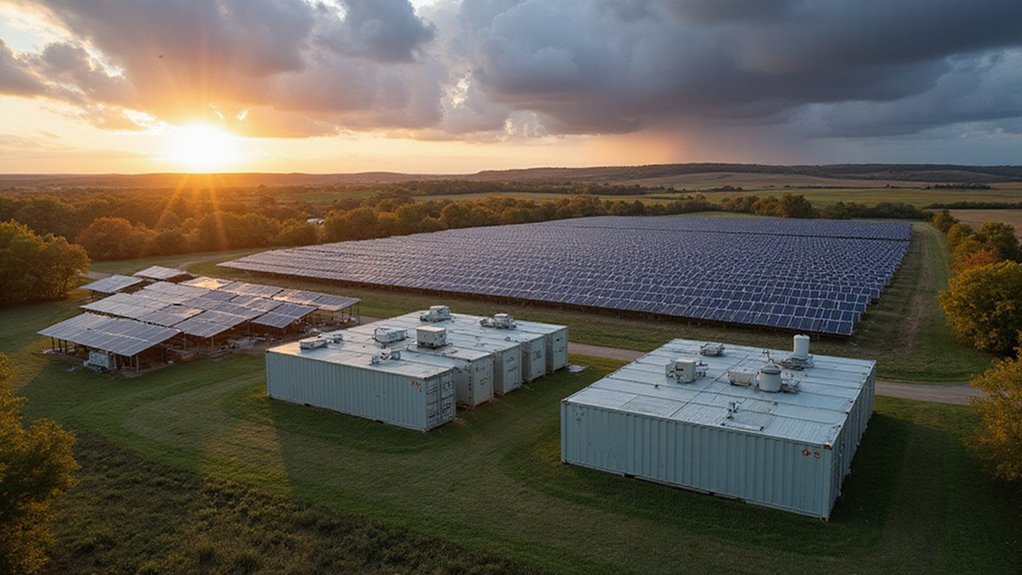

Several major automakers have postponed or completely canceled their battery manufacturing initiatives. These decisions stem from high production costs and limited access to critical materials like lithium and cobalt. As investor confidence wavers due to unstable EV demand, long-term projects are being reconsidered across the industry. Energy storage limitations continue to plague the industry, with outdated and expensive battery technology insufficient for meeting consumer expectations.

Rising interest rates and high vehicle prices are turning consumers away from electric vehicles. Many potential buyers can’t afford the upfront costs, and increased repossession rates indicate financial strain among those who have purchased EVs. Approximately 60% of potential buyers globally cite limited charging infrastructure as their top concern, especially in rural areas.

Policy changes are creating additional headwinds. In the United States, the shifting political landscape has led to uncertainty around tax credits and emissions regulations. The new Trump administration has imposed higher tariffs that will further impact international automotive trade. New tariffs on component imports are increasing costs for manufacturers, particularly affecting U.S.-China trade relationships.

Competition in the EV market has intensified dramatically. Traditional automakers and startups are fighting for a slice of limited consumer demand, triggering price wars. Meanwhile, hybrid vehicles are gaining popularity as a more affordable alternative to fully electric models. Plug-in hybrids are becoming a preferred compromise option for consumers concerned about range anxiety.

Automakers are feeling the financial pressure of high investment costs in research and development while facing shrinking profit margins. Many companies are now reassessing their product mix, balancing EVs with hybrids and traditional combustion engines to remain profitable.

As the industry navigates these challenges, it’s becoming clear that the road to an all-electric future may be longer and bumpier than many had predicted. The green dreams of rapid EV adoption are fading as market realities take hold.