Hydrogen fuel cells come together like a high-tech sandwich. The core is a special membrane called Nafion, layered between platinum catalysts that do the heavy lifting. Carbon fiber papers and precision-carved plates get stacked up with gaskets to prevent leaks. The whole assembly requires meticulous quality control – one wrong move and it’s useless. The end result? A clean energy powerhouse that turns hydrogen into electricity, with more fascinating details under the hood.

How exactly are those sleek, clean-energy powerhouses called hydrogen fuel cells made? It’s quite a process, and it starts with some pretty fancy materials – we’re talking platinum catalysts, special Nafion membranes, and enough high-tech components to make your head spin. These aren’t your grandfather’s batteries, that’s for sure. Quality control measures are implemented at the start with raw material verification.

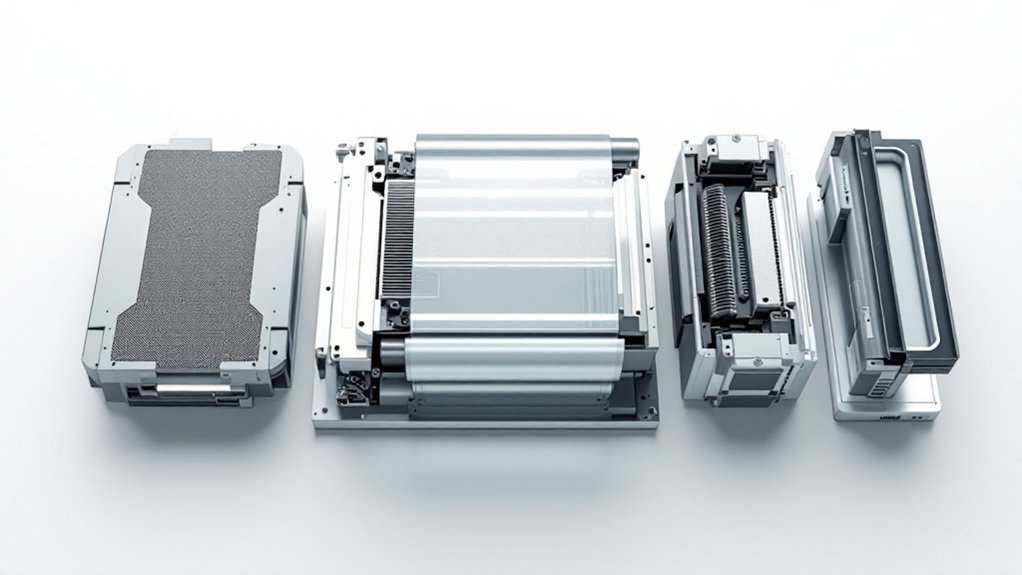

At the heart of every fuel cell is something called a membrane electrode assembly, or MEA for short. Think of it as the fuel cell’s brain. Manufacturers take a Nafion membrane and sandwich it between catalyst layers made of platinum nanoparticles – yes, actual platinum, because apparently nothing else quite does the trick. These catalyst layers get sprayed or printed onto the membrane with the precision of a Swiss watchmaker. The materials chosen must have high proton conductivity to function effectively.

The next step is adding gas diffusion layers made from carbon fiber paper. These layers need to be just right – too thick or thin and the whole thing falls apart.

Getting those carbon fiber gas diffusion layers perfectly sized is like walking a tightrope – precision is everything.

Then come the bipolar plates, usually made from graphite or metal, with intricate channels carved into them for gas flow. It’s like building a microscopic maze that hydrogen and oxygen need to navigate through.

The real magic happens during stack assembly. Individual cells get stacked together like the world’s most expensive deck of cards, with gaskets and seals making sure nothing leaks. Compression is critical – too much pressure and things crack, too little and gases escape. End plates cap off the stack, and manifolds direct the fuel and air where they need to go.

The whole manufacturing process requires incredible precision. One tiny mistake in catalyst distribution or membrane thickness can tank the fuel cell’s performance. Quality control is relentless, and manufacturers test every component multiple times.

The result? A device that can convert hydrogen into electricity with nothing but water as a byproduct. It’s basically a power plant in a box, minus the smoke stacks and environmental guilt. Not too shabby for something that started as a bunch of platinum dust and plastic sheets.