A wind turbine's generator converts the mechanical energy of spinning blades into electrical power. The main components include a rotor with magnets and a stator with wire coils. Modern generators can produce between 2-10 megawatts of power, with efficiency rates of 95-98%. Regular maintenance keeps these systems running for 20-30 years. Recent innovations like direct drive systems and smart grid integration continue advancing this clean energy technology's capabilities.

The generator is the heart of a wind turbine, converting mechanical energy from spinning blades into electrical power. Modern wind turbines use several types of generators, with doubly-fed induction generators being the most common choice. These generators allow for variable rotor speeds, which helps capture energy more efficiently across different wind conditions.

Doubly-fed induction generators enable wind turbines to efficiently convert mechanical energy into electricity by adapting to varying wind speeds.

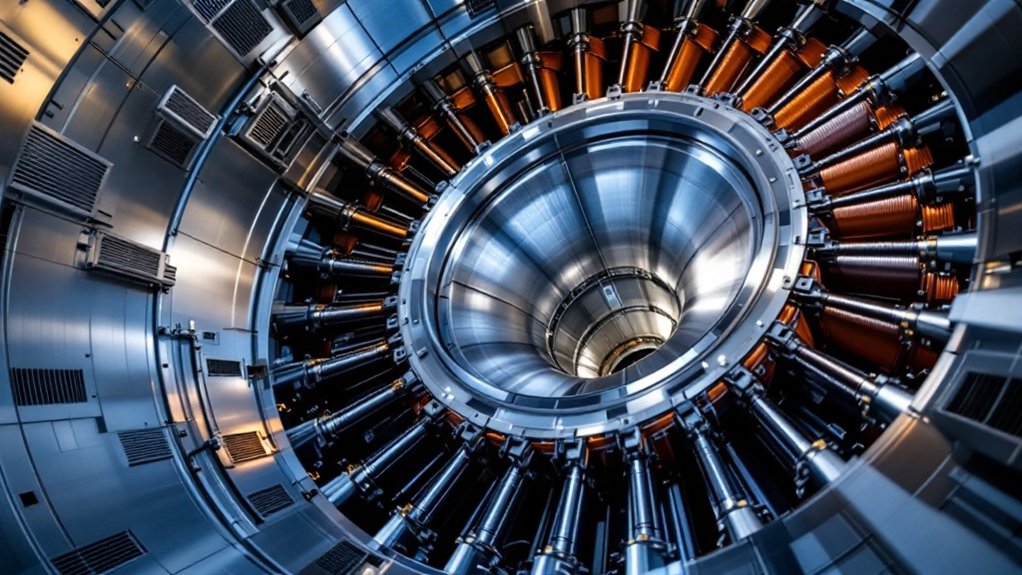

The main components of a wind turbine generator include the rotor, which contains either electromagnets or permanent magnets, and the stator, which surrounds the rotor with wire coils. Since 1987, construction has evolved to use lighter composite materials for improved efficiency and durability. Slip rings transfer power from the rotating shaft, while cooling systems prevent the generator from overheating during operation. The yaw system aligns the turbine with wind direction for optimal generator performance. Power electronics control and optimize the electrical output.

Today's onshore wind turbine generators typically produce 2-3 megawatts of power, while offshore turbines can generate more than 10 megawatts. The power output increases with wind speed until reaching the turbine's rated capacity. Wind turbines operate with a capacity factor of 35-45%, meaning they produce their maximum possible output about one-third of the time. This renewable technology provides clean electricity generation while supporting local economies through job creation and landowner income.

Modern generators achieve remarkable efficiency levels of 95-98%. Some power is lost through heat, friction, and electrical resistance, but variable speed operation helps maximize overall performance. Before connecting to the power grid, the generator's output goes through power converters and transformers to match grid requirements.

Maintaining these generators requires regular attention. Bearings typically need replacement every 5-7 years, and the winding insulation gradually degrades over time. With proper maintenance, wind turbine generators can last 20-30 years. Condition monitoring systems help detect potential failures before they occur.

The technology continues to advance with promising innovations. Superconducting generators offer the potential for higher efficiencies, while direct drive systems eliminate the need for a gearbox, reducing maintenance issues. Newer generators use higher voltage systems to reduce transmission losses, and advanced materials are improving power density.

As smart grid technology develops, these generators are becoming better integrated with modern power management systems.

Frequently Asked Questions

How Long Does a Wind Turbine Generator Typically Last Before Requiring Replacement?

Wind turbine generators typically last 20-25 years before needing replacement.

Their lifespan depends heavily on environmental conditions and maintenance quality. Offshore turbines often have shorter lifespans due to harsh salt exposure and weather.

Some well-maintained generators can operate for over 30 years, while others in challenging conditions might need replacement sooner.

Most manufacturers design their generators for a 20-30 year service life.

Can Wind Turbine Generators Operate in Freezing Temperatures?

Wind turbine generators can operate effectively in freezing temperatures, often down to -30°C.

Special cold-weather packages include heating elements, cold-resistant materials, and low-temperature lubricants. The cold actually improves performance due to higher air density.

Wind farms in Sweden, Canada, and Alaska prove these systems work in harsh winter conditions.

Manufacturers include features like sealed enclosures and de-icing systems to prevent ice damage.

What Happens to the Generator During Lightning Strikes?

Lightning strikes can cause severe damage to generators through electrical surges of up to 200,000 amps.

These powerful surges can harm generator windings, damage bearings through electrical arcing, and break down insulation.

Lightning protection systems help channel strikes safely to the ground, but generators may still need repairs or replacement after severe strikes.

Control systems can also suffer from electromagnetic interference.

How Much Maintenance Does a Wind Turbine Generator Need Annually?

Wind turbine generators require two scheduled maintenance visits per year, totaling about 20 working hours annually.

Technicians inspect electrical connections, clean components, check brushes and slip rings, and monitor vibration levels. They also test insulation and winding integrity.

Maintenance costs typically run 1.5-2% of the turbine's original cost. Older turbines and those in harsh environments need more frequent attention.

What Noise Levels Do Wind Turbine Generators Produce During Operation?

Wind turbines produce different noise levels depending on distance and conditions.

At the source, they generate 90-100 decibels, similar to a lawn mower. At typical residential distances (300 meters), the noise drops to 35-45 decibels, comparable to a refrigerator's hum.

The sound comes from two main sources: the mechanical components inside the turbine and the blades moving through air.